Undyed yak down: Finally, a natural fiber that is as practical as it is exotic and luxurious

Cashmere is sublime and warm, but lacks lanolin to provide elasticity. Therefore even the most well-knitted cashmere clothing is impractically delicate. Merino is durable and stretchy, but it’s not outrageously soft. This is because it’s sheared — that is, shaved off the animal rather than gently combed.

Via an attentive, laborious process, Bodio’s creates natural, undyed yak down that rivals merino’s sturdiness and cashmere’s softness. The three secrets are combing, de-hairing and finishing.

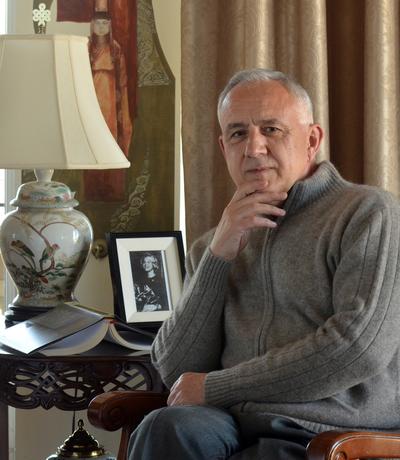

Mongolian yak down is combed from animals by nomadic herdsmen after the winter thaw, some time around June each year. “It’s not dangerous if you know what you’re doing,” says Bodio, “but even domestic yaks are quite wild. They’ll only hold still to be combed by the herder who keeps them, and often only his wife actually. Yaks are less afraid of women.”

The raw hair is collected by Bodio himself from his network in the Bayankhongor and Arkhangai provinces in central Mongolia, and delivered by trucks to his de-hairing facility in the Mongolian capital city of

Ulaanbaatar, or “UB” as it’s colloquially known. Here it is sorted by color, washed, and de-haired.

Metaphorically, de-hairing is like whisky or cognac distillation, a procedure for transforming raw material into a glorious, essential elixir.

Most companies will run a batch of raw yak fiber through the dehairing machines four or five times, losing some 2/3 of the bulk in the process. Bodio’s, however, insists on an extraordinary seven or eight de-hairing passes. This results in a drawdown of 80% of the original mass. The exquisite 20% that remains is known in the trade as “tops.”

After the yak down tops are spun into yarn and knitted into garments, Bodio’s best-in-class finishing techniques assure a final product with an almost unimaginably soft “hand” (the industry term for how a textile feels to the fingertips).

-

04hours

Mongolian platinum yak down is one hundred times more rare than cashmere

Bodio’s has made a specialty and an art out of collecting, processing and knitting this ... -

04hours

Fascination: sophisticated apparel from an untamed land of nomads and conquerors

Anthropology professor Jack Weatherford is the author of the New York Times bestseller Genghis Khan ... -

04hours

Do goats damage pasture? No they don't

Environmental issues are also of a concern for us. When it comes to cashmere business, ... -